In any workshop, garage, or even a well-equipped home, tools are the lifeblood of productivity and problem-solving. Yet, over time, a collection of essential implements can easily spiral into a disorganized mess, leading to wasted time searching for that elusive wrench or discovering redundant purchases. Imagine the frustration of a professional mechanic losing precious minutes on a job because a critical specialty tool is missing, or a dedicated DIYer buying a third drill bit set because they couldn’t find the first two.

This common challenge highlights a universal need for systematic organization, and that’s precisely where a well-structured mechanic tool inventory list template becomes an invaluable asset. This document isn’t just about counting what you own; it’s a strategic planning tool designed to enhance efficiency, reduce costs, and instill a sense of calm in even the busiest of environments. Whether you manage a large auto repair shop, a bustling fabrication studio, or simply take pride in a meticulously organized personal workshop, adopting a comprehensive tool tracking system can transform your approach to work and maintenance.

The Indispensable Role of Structured Documentation

The foundation of any efficient operation, from a bustling corporate office to a single-person garage, lies in well-organized information. When it comes to managing physical assets like tools, a structured list isn’t merely a suggestion—it’s a critical component of operational excellence. Without a clear framework, inventory management devolves into guesswork, leading to inefficiencies, unnecessary expenses, and potential safety hazards.

A well-designed template provides that essential structure, turning a chaotic collection into a manageable asset. It acts as a single source of truth, detailing what tools you possess, where they are located, and their current condition. This systematic approach ensures that every item has a place and every place has an item, bringing order to what might otherwise be a jumbled array of equipment. Such documentation empowers better decision-making, from procurement to project planning, by giving you an immediate and accurate overview of your resources.

Unlocking the Multitude of Key Benefits

Implementing a detailed inventory system offers far more than just a tidy workspace; it delivers tangible advantages that impact both the bottom line and daily operational flow. These benefits extend from enhanced clarity to significant financial savings, proving that a little upfront organization goes a long way. This planning tool is a strategic investment in efficiency.

One of the primary advantages is unparalleled clarity. Knowing exactly what you have on hand eliminates ambiguity and reduces the time spent searching for specific tools. This clarity extends to accountability, as shared tools can be tracked more effectively, minimizing loss or misplacement. Another significant benefit is time-saving. Imagine the hours accumulated over a year that are otherwise spent rummaging through drawers or bins. A quick glance at an inventory checklist can pinpoint the exact location of any tool, freeing up valuable time for actual work.

Furthermore, a consistent inventory list promotes operational consistency. For businesses with multiple employees, this ensures that everyone follows the same system for tool retrieval and return, fostering a more disciplined work environment. It also simplifies the process of onboarding new team members, providing them with a clear guide to the workshop’s assets. Lastly, improved tool management translates into better financial planning. By accurately tracking existing tools and their condition, you can avoid redundant purchases, identify items needing replacement proactively, and even inform insurance valuations. This proactive approach to asset management can lead to substantial cost reductions over time.

Tailoring Your Inventory for Any Scenario

One of the greatest strengths of an inventory template is its inherent adaptability. While the core concept remains the same, the level of detail and specific categories can be easily modified to suit vastly different needs, from a casual hobbyist to a professional enterprise. This versatility ensures that the mechanic tool inventory list template can serve as a valuable asset across numerous contexts.

For the personal workshop, a simpler version might focus on major power tools, specialty hand tools, and consumables. The goal here is usually convenience and avoiding duplicate purchases, making it a functional guide for personal projects. Household use expands this concept to cover general repair kits, gardening tools, and even seasonal equipment, helping homeowners keep track of diverse items scattered across a property.

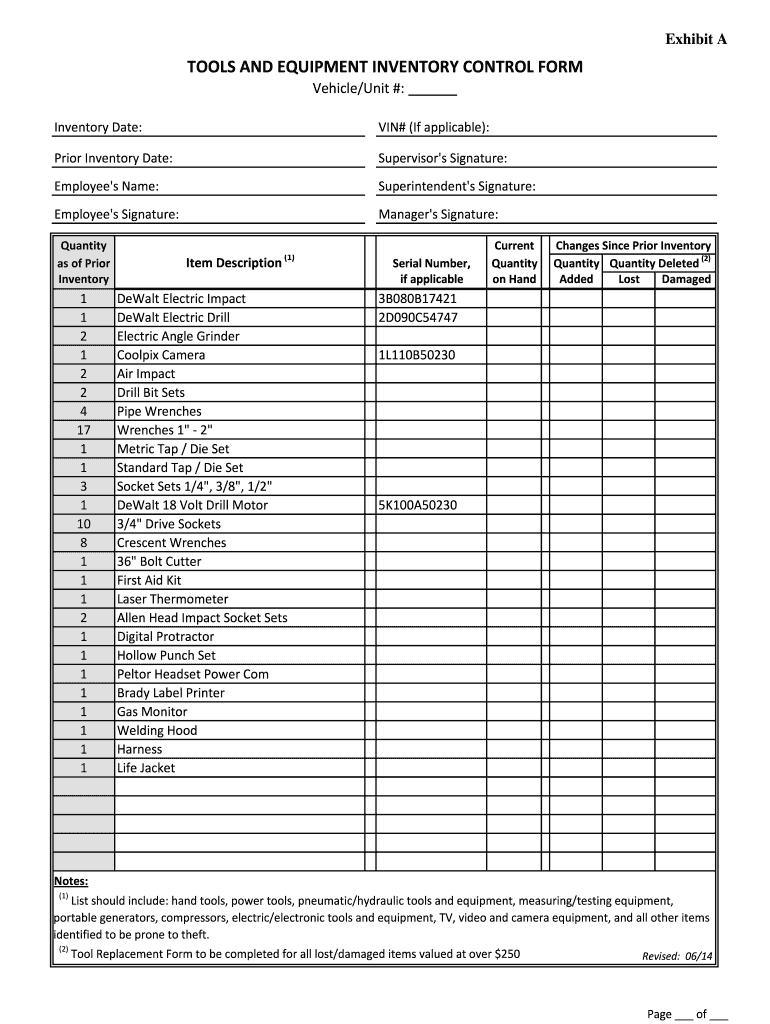

In a professional auto repair shop or a large industrial facility, the template becomes a mission-critical document. Here, it must be comprehensive, tracking everything from common wrenches to highly specialized diagnostic equipment, often incorporating details like serial numbers, calibration dates, and designated storage locations. This detailed approach supports regulatory compliance, efficient resource allocation, and advanced asset tracking. Even educational settings, such as vocational schools, can benefit immensely from a customized checklist to manage shared tools, ensuring students have access to the right equipment and learn the importance of organization. The power lies in its ability to scale and customize, transforming it into your ideal tool tracking planner.

Core Elements of an Effective Tool List

Regardless of its specific application, any robust tool inventory needs to include several fundamental pieces of information to be truly effective. These core components ensure comprehensive tracking and ease of use.

- Item ID/SKU: A unique identifier for each tool or set of tools. This can be a simple sequential number or a more complex alphanumeric code for larger inventories.

- Tool Name/Description: A clear, concise name that accurately describes the item, e.g., “1/2-inch Drive Ratchet” or “Digital Multimeter.”

- Category: Group tools into logical categories such as Hand Tools, Power Tools, Diagnostic Equipment, Air Tools, Specialty Tools, Consumables, etc. This aids in organization and searching.

- Quantity On Hand: The current count of each tool. This is crucial for reordering and identifying missing items.

- Location: Specify where the tool is stored, e.g., “Toolbox A, Drawer 3,” “Workbench Top Shelf,” “Service Van 2,” or “Storage Cabinet.”

- Condition: A quick assessment of the tool’s status (e.g., New, Good, Fair, Needs Repair, Broken). This helps prioritize maintenance and replacements.

- Purchase Date/Vendor: Record when and from whom the tool was acquired. Useful for warranty claims, depreciation, and future purchasing decisions.

- Estimated Value: The approximate current or original cost of the tool, important for insurance and asset accounting.

- Notes/Maintenance Log: A section for additional details, such as serial numbers, calibration dates, last service date, or any specific quirks of the tool.

- Last Inventoried Date: A timestamp indicating when the tool was last physically checked and updated on the list. This helps maintain accuracy.

Designing for Maximum Readability and Usability

An inventory list, no matter how comprehensive, is only as good as its usability. A poorly designed document can deter consistent use, negating all the potential benefits. Therefore, special attention must be paid to the design, layout, and accessibility of your tool tracking document, whether it’s a physical printout or a digital file.

For digital formats, such as spreadsheets (Excel, Google Sheets) or dedicated inventory software, focus on clear column headers, consistent data entry (e.g., dropdown menus for categories or locations), and filter/sort functionalities. Conditional formatting can be employed to highlight tools needing maintenance or those with low quantities. Ensure the file is easily accessible by all authorized users, perhaps via a shared cloud drive, and establish clear version control protocols to prevent conflicting edits. Digital templates also offer the advantage of search functions, quickly locating specific items across thousands of entries.

When designing for printable formats, prioritize clarity and ample white space. Use legible fonts and a consistent layout. Group related information visually, perhaps by category or location, to make scanning easier. Consider using checkboxes for ‘found’ items during physical checks. Laminated copies can withstand workshop environments better, and providing clipboards for manual updates before digital transfer can streamline the process. Ultimately, the goal is to make the inventory process as intuitive and least burdensome as possible, encouraging regular updates and sustained adherence to the system.

Implementing a robust tool inventory list isn’t just about meticulous record-keeping; it’s about empowering smarter work. By adopting a systematic approach to tracking your valuable assets, you gain more than just an organized workshop; you gain peace of mind and operational agility. This strategic document transforms the mundane task of managing tools into a powerful lever for enhanced productivity and reduced operational friction.

Embracing the structure offered by a well-designed mechanic tool inventory list template allows individuals and businesses alike to make informed decisions, minimize waste, and reclaim valuable time. It’s a testament to the idea that preparation and organization are not merely desirable traits, but essential components of sustained success in any hands-on endeavor. Start building your comprehensive tool tracking system today and experience the profound benefits of a truly organized environment.