In an increasingly complex world, managing our physical environment, whether at home or in the workplace, has become a cornerstone of both safety and productivity. We often meticulously organize digital files or financial documents, yet overlook the physical items that pose potential risks if mishandled or forgotten. This is particularly true for hazardous chemicals, which, despite their essential utility, demand careful tracking and management. A well-structured chemical inventory is not merely a formality; it’s a critical tool for maintaining order, ensuring safety, and providing invaluable peace of mind.

For anyone who stores cleaning supplies under the sink, keeps paints and solvents in the garage, manages laboratory reagents, or operates a manufacturing facility, understanding what you have, where it is, and its potential hazards is paramount. This goes beyond just knowing you "have some bleach" – it means having detailed information readily accessible. The benefits extend from facilitating quick responses in emergencies to optimizing purchasing, ensuring proper disposal, and, for businesses, achieving regulatory compliance. A dedicated system, like a robust hazardous chemical inventory list template, is the most efficient way to achieve this level of oversight.

The Power of Structured Documentation

The human brain is an incredible tool, but its capacity for perfect recall of detailed, diverse information is limited. This is precisely why we rely on external systems for organization. Structured documentation, whether it’s a project timeline, a daily task tracker, or a comprehensive chemical log, transforms chaotic information into actionable intelligence. It provides an objective record that doesn’t rely on memory, reducing errors and ensuring consistency across tasks and users. In essence, a well-designed list acts as an extension of our cognitive abilities, making complex information manageable and accessible.

For items that carry inherent risks, like hazardous chemicals, this structured approach isn’t just about tidiness; it’s about risk mitigation. Knowing the precise location, quantity, and safety information for every chemical on your premises drastically reduces the potential for accidents, spills, or improper use. This proactive management prevents small issues from escalating into significant problems, safeguarding both people and property. Embracing a systematic record-keeping method is a clear sign of a commitment to safety and operational excellence.

Unlocking Efficiency: Benefits of a Dedicated Template

Adopting a specialized inventory template offers a multitude of advantages that go far beyond simple record-keeping. Firstly, it provides unparalleled clarity. Instead of vague notes or mental approximations, you gain a precise snapshot of your chemical holdings, complete with all necessary details. This clarity is crucial for anyone needing quick information, whether it’s a family member searching for a specific product or an emergency responder assessing a situation.

Secondly, the time-saving aspect is immense. Imagine needing to find a Safety Data Sheet (SDS) for a particular solvent or wanting to know the expiration date of a pesticide. Without a centralized list, this can involve rummaging through cabinets, deciphering faded labels, or sifting through physical files. With an organized template, this information is just a glance away, significantly reducing wasted time and frustration. Consistency is another major benefit; a template ensures that all essential data points are captured for every item, preventing crucial information from being overlooked, regardless of who is performing the inventory. This standardized approach makes updates easier and ensures that the information remains reliable and current over time.

Tailoring Your Inventory for Every Scenario

One of the greatest strengths of a well-designed inventory list is its adaptability. While the core purpose remains consistent – tracking hazardous chemicals – the specifics can be finely tuned to suit diverse environments and needs.

For personal or household use, the focus shifts to everyday items. This might include a detailed accounting of cleaning products, garage chemicals like motor oils and paint thinners, garden pesticides, or even hobby-specific chemicals such as photographic developers. Here, the template serves primarily as a safety checklist for family members, especially children or pets, and a crucial reference in case of an accidental exposure or a fire. It helps you understand proper storage requirements and informs responsible disposal practices, transforming your home into a safer, more organized living space.

In a small business or professional setting, the template becomes an indispensable tool for compliance and operational efficiency. Imagine a small manufacturing plant, a craft brewery, a dental office, or even a landscaping company. They all handle various chemicals critical to their operations. For these entities, the inventory helps in meeting OSHA (Occupational Safety and Health Administration) regulations, managing Safety Data Sheets (SDSs) effectively, and ensuring employees are aware of potential hazards and emergency procedures. It’s also vital for inventory management, preventing overstocking, reducing waste, and streamlining purchasing decisions. The inventory can even be adapted for specific departmental needs, such as tracking laboratory reagents in a research facility or detailing janitorial supplies in a large office building.

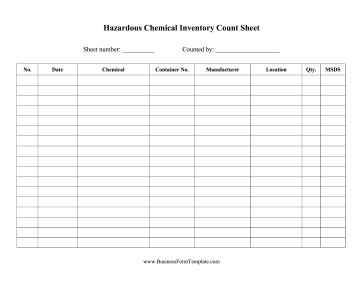

Core Elements of an Effective Chemical Inventory

A truly effective chemical inventory list isn’t just a simple jotting down of names; it’s a comprehensive data set designed for maximum utility and safety. Regardless of whether you’re using a printable sheet or an editable digital document, certain key components are non-negotiable for a truly robust inventory:

- Chemical Name (Common & IUPAC if applicable): This includes the everyday name people use and, where relevant, the more precise scientific name to avoid confusion.

- Product Name/Brand: The specific product label name, like “Clorox Bleach” or “WD-40 Multi-Use Product.”

- Manufacturer/Supplier: Who produced the chemical and where you purchased it from, valuable for sourcing additional information or reordering.

- Container Size/Quantity: Helps track how much you have (e.g., 1-gallon jug, 500 mL bottle, 3 of 12 oz cans).

- Location (specific storage area): Crucial for quick retrieval during emergencies or routine tasks (e.g., “Under Kitchen Sink,” “Garage Shelf B,” “Lab Cabinet 3”).

- Date Acquired/Opened: Essential for monitoring shelf life and proper rotation of stock.

- Expiration Date: Many chemicals degrade over time; knowing this prevents the use of ineffective or potentially unstable products.

- Hazard Class/Pictograms (GHS): Identifies the primary risks (e.g., Flammable, Corrosive, Toxic) using universally recognized GHS pictograms for immediate visual recognition.

- SDS Location/Reference: Where can the full Safety Data Sheet be found? This could be a physical binder location, a file path on a computer, or a web link.

- Disposal Information: How should this chemical be safely disposed of when it’s no longer needed or expired? This is vital for environmental protection.

- Emergency Contact/Procedure: Quick reference for what to do in case of a spill, exposure, or fire involving this specific chemical.

- Notes/Special Instructions: Any additional pertinent information, such as “Requires ventilation,” “Do not mix with X,” or “Only authorized personnel.”

Designing for Clarity and Usability

The best inventory is one that is actually used and understood. This means paying close attention to its design and layout, whether you’re creating a printable checklist or an editable spreadsheet. Start with clear headings and a logical flow that guides the user through each data point. Ample spacing between entries and columns prevents the document from looking cluttered and makes it easier to read quickly, especially in a stressful situation.

Consistent formatting, including font sizes and styles, enhances readability and professionalism. Consider incorporating color coding for certain categories; for instance, using a distinct background color for chemicals requiring special handling or those nearing expiration. For digital formats, leverage technology: make fields searchable, use dropdown menus for common entries (like locations or hazard classes), and embed links directly to SDS documents. Cloud-based solutions offer accessibility from multiple devices and ensure data backup. If the list is intended for a physical location that might get messy, like a workshop or laboratory, consider printing it on durable paper and laminating it. Regardless of the format, schedule regular review and update sessions to keep the information current, ideally quarterly or bi-annually, to reflect new purchases, disposals, or changes in storage.

The effort invested in creating and maintaining a comprehensive hazardous chemical inventory list template pays dividends in safety, efficiency, and overall organization. It transforms a potentially overwhelming task into a manageable and systematic process, reducing stress and boosting productivity for both individuals and organizations. By providing a clear, consistent, and easily accessible record of every chemical you possess, this powerful organizational tool empowers you to respond confidently to any situation, ensuring the well-being of those around you and safeguarding your environment.

Ultimately, a robust hazardous chemical inventory list template isn’t just about listing items; it’s about building a foundation of preparedness and control. It’s a proactive step towards a safer, more efficient existence, offering invaluable peace of mind that comes from knowing exactly what’s at hand and how to manage it responsibly. Embrace this essential planning document, and you’ll find that managing chemicals becomes not a burden, but a testament to smart organization and a commitment to safety.