In the dynamic world of business and asset management, especially where significant capital is tied up in machinery, a robust organizational system isn’t just a convenience—it’s a critical operational necessity. From bustling construction sites to expansive agricultural operations, or even a personal collection of cherished antique tractors, the efficient tracking and maintenance of valuable equipment can make or break productivity and profitability. Without a clear, systematic approach, businesses and individuals risk costly oversights, inefficient resource allocation, and even potential financial losses.

This is where a dedicated system like a heavy equipment inventory template becomes an invaluable asset in itself. It’s more than just a list; it’s a strategic framework designed to bring clarity, control, and foresight to your equipment management. By standardizing how you record, track, and monitor your machinery, this tool empowers you to optimize operational efficiency, ensure compliance, and make informed decisions, ultimately safeguarding your investments and streamlining workflows for anyone from a fleet manager to a hobbyist with a significant workshop.

The Power of Structured Documentation

Imagine trying to manage a fleet of excavators, forklifts, or specialized agricultural machinery with only a mental tally or scattered notes. The potential for errors, missed maintenance, and misplaced assets is enormous. Structured documentation, like a well-designed inventory checklist, eliminates this chaos by providing a consistent, reliable repository for all essential information. It transforms abstract knowledge into concrete, actionable data.

Utilizing a template ensures that every piece of equipment is accounted for and systematically monitored. This structured approach is vital for more than just organization; it’s foundational for effective asset lifecycle management, from acquisition to eventual retirement. It minimizes human error, fosters accountability, and creates a single source of truth for all stakeholders, whether they are operators, maintenance technicians, or financial controllers.

Unlocking Key Operational Advantages

Implementing a comprehensive heavy equipment inventory template brings a multitude of benefits that extend far beyond mere record-keeping. These advantages contribute directly to improved operational efficiency, reduced costs, and enhanced decision-making across the board.

- Enhanced Clarity and Transparency: A standardized inventory provides a clear, uniform overview of all your equipment. Everyone, from the project manager to the service technician, can access the same up-to-date information, reducing confusion and fostering better collaboration. This transparency is crucial for daily operations and long-term planning.

- Significant Time Savings: Without a proper system, tracking down information about a specific piece of equipment—its last service, current location, or serial number—can be a time-consuming scavenger hunt. A well-organized template allows for quick retrieval of critical data, freeing up valuable time for more productive tasks and reducing administrative overhead.

- Consistency and Standardization: Templates enforce a consistent method of data entry, ensuring that all information is recorded in a uniform format. This standardization is invaluable for comparing assets, generating reports, and integrating with other operational systems, providing a reliable foundation for all equipment-related activities.

- Informed Decision-Making: Access to accurate and complete data about your equipment’s age, condition, maintenance history, and operational costs empowers you to make smarter decisions. This includes optimizing equipment utilization, planning for timely replacements, identifying underperforming assets, and negotiating better deals on purchases or sales.

- Compliance and Risk Management: Many industries are subject to strict regulatory requirements regarding equipment safety, maintenance, and record-keeping. A detailed inventory helps ensure compliance with these regulations, mitigating legal risks and facilitating smoother audits. It also provides essential documentation for insurance claims or warranty issues.

- Proactive Maintenance Scheduling: By meticulously tracking service dates, hours of operation, or mileage, your inventory system allows for the proactive scheduling of preventive maintenance. This approach minimizes unexpected breakdowns, extends the lifespan of your machinery, and reduces costly emergency repairs, ensuring maximum uptime.

Tailoring Your Asset Management System

One of the greatest strengths of a robust equipment tracking solution is its adaptability. While the core principles remain consistent, the specific fields and depth of detail can be customized to suit a wide range of needs, from sprawling corporate fleets to specialized personal collections.

For large-scale business operations, such as construction companies, mining enterprises, or heavy equipment rental agencies, the template can be extensively detailed. This might include fields for specific project assignments, estimated depreciation schedules, detailed fuel consumption logs, GPS tracking integration, and complex financial data for lease versus buy analyses. The focus here is on maximizing utilization, minimizing downtime across multiple sites, and optimizing financial returns on significant capital investments.

Agricultural businesses might adapt their inventory checklist to include data relevant to seasonal usage, specific crop applications, or regulatory compliance unique to farming machinery. Tracking hours during harvest season versus planting season, or detailing specialized attachments for various farming tasks, becomes crucial for maximizing yield and machine lifespan.

Even individuals or small businesses managing a handful of significant assets can benefit immensely. Perhaps it’s a dedicated mechanic with a range of specialized tools, a homeowner with a tractor and various landscaping attachments, or a collector of vintage vehicles. In these scenarios, the emphasis might shift to personal identification markers, detailed service records from trusted local mechanics, and specific notes on storage conditions or sentimental value. The beauty of such a document lies in its ability to scale and prioritize information based on what truly matters to the user, ensuring that even a personal collection is managed with professional precision.

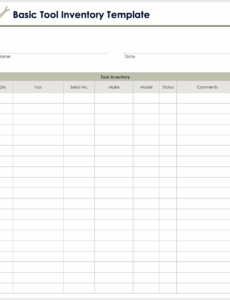

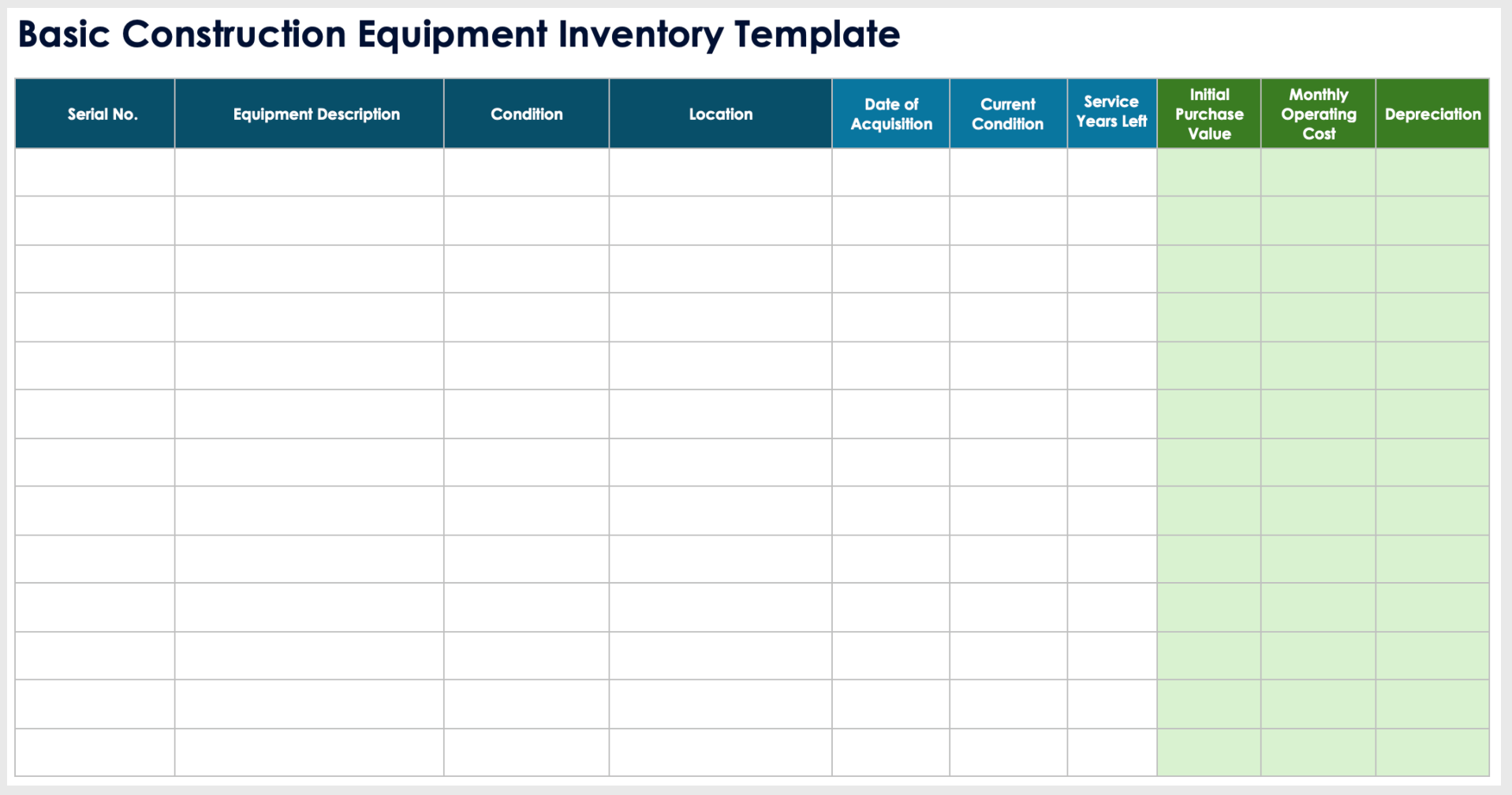

Essential Elements of an Effective Inventory Checklist

To be truly valuable, any inventory template, especially one for heavy equipment, must capture comprehensive and relevant data points. The following components represent the foundational sections that every effective list should include to provide a holistic view of each asset:

- **Basic Identification Data:**

- Asset ID Number (unique internal identifier)

- Equipment Name/Type (e.g., Excavator, Forklift, Tractor)

- Manufacturer

- Model Number

- Serial Number (crucial for tracking and insurance)

- Year of Manufacture

- **Acquisition and Financial Details:**

- Purchase Date

- Original Purchase Price

- Vendor/Supplier

- Warranty Information (expiration date, coverage details)

- Depreciation Schedule (if applicable)

- Current Estimated Value

- **Location and Status:**

- Current Location (e.g., Job Site A, Warehouse B, Personal Garage)

- Assigned Project/Department (for business use)

- Status (e.g., In Use, Stored, Under Maintenance, Retired)

- Availability (e.g., Ready, Booked, Awaiting Repair)

- **Maintenance and Operational Records:**

- Last Service Date

- Next Service Due (date or hour meter reading)

- Service History Log (link to detailed records or summary)

- Current Hour Meter Reading / Odometer Reading

- Fuel Type

- Last Safety Inspection Date

- **Legal and Insurance Information:**

- Insurance Policy Number

- Insurance Coverage Details

- Lienholder Information (if financed)

- Registration/License Plate Number (if applicable)

- **Condition Assessment and Documentation:**

- Current Condition Notes (e.g., “Good,” “Fair,” “Needs Repair”)

- Date of Last Condition Assessment

- Link to Photos/Videos of Equipment (initial state, post-repair)

- Record of Major Repairs/Modifications

- **Attachments and Accessories:**

- List of compatible attachments (e.g., buckets, forks, plows)

- Serial numbers or IDs for major attachments

- **General Notes/Remarks:**

- An open field for any additional pertinent information, special instructions, or historical context.

Enhancing Readability and Practical Use

A well-structured document is only effective if it’s easy to read, understand, and use. Thoughtful design and user experience considerations are paramount, whether you opt for a digital spreadsheet, a database solution, or a printable binder-ready format.

Firstly, simplicity and clarity should guide your design choices. Avoid cluttering the layout with unnecessary elements. Use clear, concise headings and labels that are intuitive to understand. Consistent formatting, including font styles, sizes, and spacing, enhances readability and makes it easier to scan for specific information. For digital versions, leverage features like dropdown menus for consistent data entry (e.g., for "Status" or "Location"), conditional formatting to highlight critical dates (like upcoming maintenance), and searchable fields for quick data retrieval. Cloud-based solutions offer collaborative access and ensure data backup, allowing multiple team members to update and access the information securely from anywhere.

For printable formats, ensure there’s ample space for handwritten entries if that’s the primary method of data capture. Use sturdy paper and consider organizing pages in a durable binder with clear dividers for easy navigation. Both digital and print versions should prioritize logical flow, grouping related information together. Regardless of the format, regular review and updating of the template itself are essential. As your needs evolve or new types of equipment are acquired, your inventory system should adapt. Implementing version control for digital templates ensures that everyone is always working with the most current iteration. Finally, providing brief training or guidelines to users on how to accurately complete and maintain the records will significantly improve the overall utility and data integrity of your equipment inventory.

Ultimately, adopting a well-crafted heavy equipment inventory template is an investment that pays dividends in operational efficiency and financial security. It transforms the often-overwhelming task of managing valuable machinery into a streamlined, predictable process. By moving from reactive problem-solving to proactive asset management, businesses and individuals can significantly reduce costs associated with downtime, lost equipment, and inefficient scheduling.

This practical approach ensures that every piece of equipment is not just accounted for, but actively managed throughout its lifecycle. It fosters an environment of organization, accountability, and foresight, empowering you to make strategic decisions that optimize your resources. Embracing this powerful organizational tool is a clear step towards greater productivity, peace of mind, and a more robust financial future for your operations, no matter their scale.