In an increasingly complex world, maintaining order is not just a preference, it’s a strategic advantage. Whether you’re managing a bustling household, overseeing a small business, or tackling a large-scale industrial project, the sheer volume of assets, tools, and components can quickly become overwhelming. Lost time searching for a specific item, duplicated purchases due to forgotten stock, or safety hazards from uninspected equipment are all direct consequences of poor organization. This is especially true when dealing with electrical components and equipment, where precision and accountability are paramount.

This article delves into the critical role of a well-structured electrical inventory list template. Far more than just a simple checklist, this specialized document serves as a powerful productivity tool designed to bring clarity, efficiency, and safety to any environment where electrical items are present. It’s for the homeowner wanting to keep track of spare fuses and light fixtures, the small contractor needing to manage their tools and supplies, and the facilities manager ensuring compliance and operational readiness. By providing a clear, consistent framework, such a template transforms chaos into control, ensuring every essential item is accounted for, easily locatable, and properly maintained.

The Power of Structured Documentation

The human brain, while incredibly capable, thrives on structure. When faced with a multitude of items, tasks, or pieces of information, a systematized approach significantly reduces cognitive load and the likelihood of error. This principle applies directly to inventory management, where an unstructured approach often leads to inefficiency and frustration. Relying on memory or haphazard notes for critical components is a recipe for disaster, especially in environments where safety and operational continuity are key.

Structured documentation, like a dedicated template, provides a predictable framework. It ensures that every necessary piece of information is recorded in a consistent manner, making data retrieval and analysis straightforward. Instead of scrambling to remember where a particular cable length is stored or when a power tool was last inspected, a quick glance at the organized record provides immediate answers. This foundational layer of order is what elevates simple record-keeping into a strategic asset, empowering individuals and organizations to operate with greater confidence and precision.

Unlocking Efficiency with Standardized Records

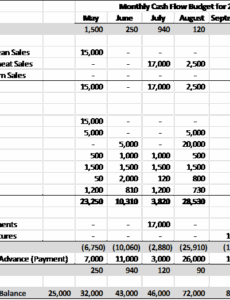

The advantages of implementing a standardized record for your electrical assets extend far beyond mere tidiness; they translate directly into tangible benefits for productivity and financial well-being. One of the most significant gains is enhanced clarity. When every item is documented consistently, there’s no ambiguity about what you have, where it is, or its condition. This clear overview facilitates better planning and decision-making, from procurement to project allocation.

Time-saving is another paramount advantage. Imagine the hours reclaimed from not having to search for misplaced tools or double-checking stock levels manually. A well-maintained inventory record allows for quick identification and retrieval, streamlining workflows and reducing downtime. Furthermore, it fosters consistency across operations, ensuring that new team members can quickly understand and contribute to the system, and that all items are managed according to the same standards. This consistency helps to prevent mistakes, minimize waste, and ensure compliance with safety regulations, making the investment in a robust organizational tool highly worthwhile.

Tailoring Your Inventory for Every Need

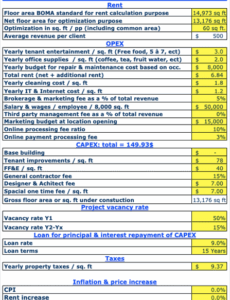

The beauty of a well-designed inventory system lies in its adaptability. While the core purpose of tracking electrical items remains constant, the specific details and scope will naturally vary depending on the context. A household might need a relatively simple checklist, while a large industrial operation requires a far more intricate and detailed system. The flexibility of a template means it can be scaled up or down, or customized with specific fields relevant to the user’s unique circumstances.

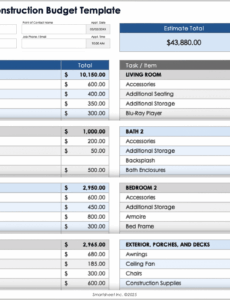

For personal or household use, a basic inventory might focus on common items like extension cords, surge protectors, spare light bulbs, batteries, and small appliances. The goal here is quick accessibility and ensuring essentials are always on hand. Businesses, on the other hand, might adapt this list to track power tools, heavy machinery, specialized wiring, circuit breakers, safety equipment, and even diagnostic instruments. The core template can serve as a foundational guide, with users adding or removing categories, fields, and detail levels to perfectly match their operational requirements, turning a general tool into a highly specialized asset for their specific documentation needs.

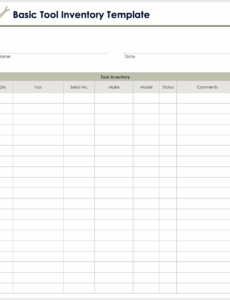

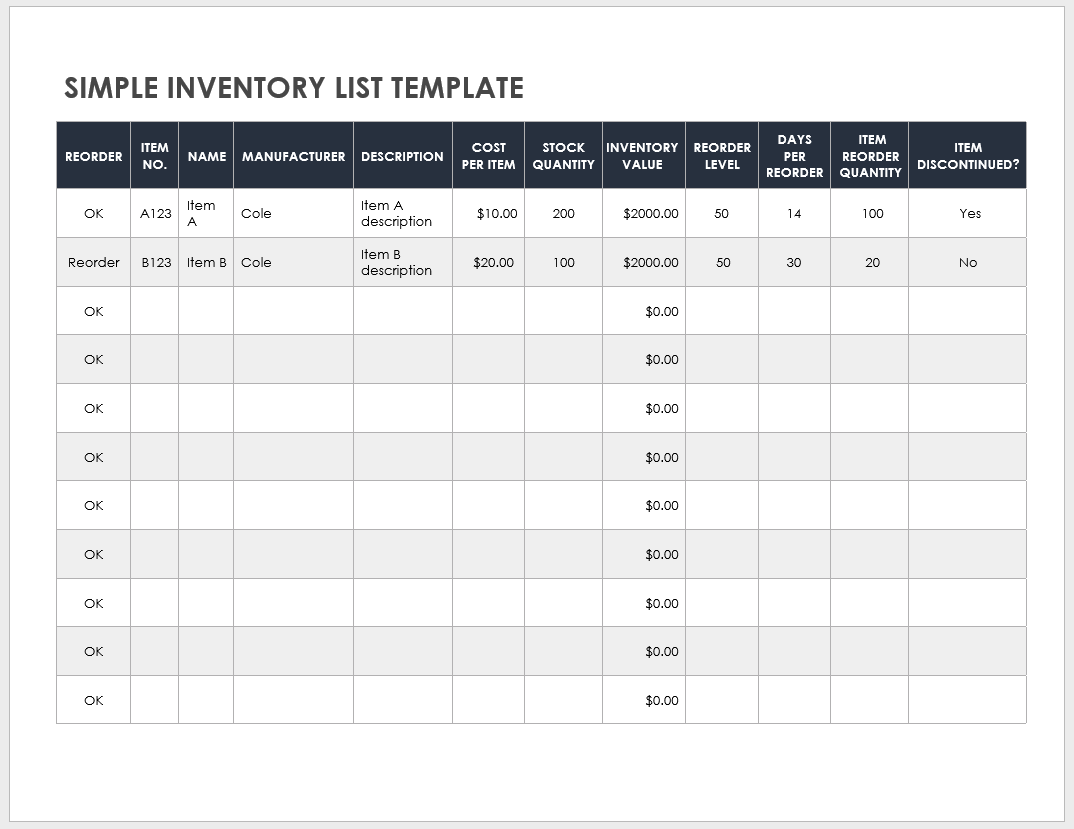

Anatomy of a Comprehensive Electrical Record

An effective inventory record is more than just a list of names; it’s a detailed data sheet for each item. To be truly valuable, it should include specific categories that provide a complete picture of every electrical asset. Here are the essential components every robust template should incorporate:

- Item Name/Description: A clear and concise name for the item (e.g., "12-Gauge Extension Cord," "LED Smart Bulb," "Digital Multimeter").

- Unique Identifier/SKU: A distinct code or number for easy tracking, especially useful for businesses with many similar items.

- Quantity: The number of units currently on hand.

- Location: Specific storage area (e.g., "Garage Shelf A-3," "Tool Room Cabinet 2," "Server Rack 4U").

- Manufacturer/Brand: The company that produced the item, useful for replacements or warranty claims.

- Model Number: The specific model designation, critical for compatibility and ordering parts.

- Serial Number: A unique identifier for high-value or regulated items, essential for warranty, theft prevention, and tracking.

- Date of Purchase/Acquisition: Helps track asset age and warranty periods.

- Cost/Value: The purchase price or estimated current value, important for budgeting and insurance.

- Condition: Current state of the item (e.g., "New," "Used – Good," "Needs Repair").

- Maintenance/Inspection Date: Date of last service or inspection, crucial for safety and operational readiness.

- Next Maintenance Due: Scheduled date for future service, ensuring preventative care.

- Supplier/Vendor: Where the item was purchased, useful for reordering or returns.

- Notes/Comments: Any additional relevant information, such as specific project assignments, repair history, or special instructions.

- Status: (e.g., "In Use," "In Storage," "Disposed," "Loaned Out").

These points collectively ensure that the document provides a holistic view, transforming it from a simple checklist into a powerful management tool for any electrical inventory.

Enhancing Usability: Design & Accessibility

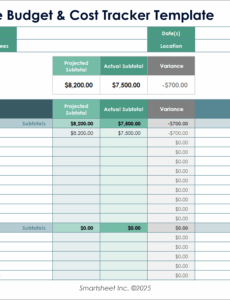

Creating a comprehensive inventory is only half the battle; ensuring it’s easy to use, read, and maintain is equally crucial. The design and accessibility of your document can significantly impact its adoption and effectiveness. Whether you prefer a physical printout or a digital spreadsheet, thoughtful design principles will make your organizational efforts more successful.

For printed documents, focus on clear typography, adequate white space, and logical flow. Use headings and subheadings to break up information, and consider using a consistent color scheme or bolding for key data points. Ensure the layout is not overly crowded, leaving room for handwritten notes if necessary. For digital formats, readability is still key. Utilize features like freeze panes in spreadsheets to keep headings visible when scrolling, implement data validation for consistent entries, and consider conditional formatting to highlight items needing attention (e.g., low stock, overdue maintenance). Providing both printable and editable versions caters to diverse user preferences. The goal is to make the inventory a living, breathing document that encourages regular updates and provides information at a glance, maximizing its value as a productivity tool.

Regardless of format, maintaining version control is important. If multiple people are accessing or updating the record, ensure there’s a system to track changes and prevent accidental overwrites. Cloud-based solutions with real-time collaboration features are excellent for digital files, while a clear labeling system (e.g., "Inventory_Q3_2023_Final.pdf") helps manage printed versions. Regular reviews and updates are paramount; an outdated inventory is as unhelpful as no inventory at all. Schedule periodic checks to verify accuracy, dispose of obsolete items, and add new acquisitions to keep your records current and reliable.

The implementation of a dedicated electrical inventory list template represents a significant step towards optimized organization and enhanced productivity. It empowers individuals and teams to move beyond reactive problem-solving, fostering a proactive approach to managing valuable assets. By providing a clear, consistent, and adaptable framework, this tool ensures that every component, from a simple light bulb to complex machinery, is tracked, maintained, and readily available.

Ultimately, investing time in setting up and regularly updating such a systematic record pays dividends by reducing waste, improving safety, and saving countless hours of searching and reordering. Embrace the power of structured documentation; it’s a small change that yields substantial improvements in efficiency and peace of mind for anyone dealing with electrical equipment.