In the intricate world of modern manufacturing, where supply chains stretch across continents and production hinges on precision, the foundational strength of business relationships is paramount. A clear, legally sound framework is not just a preference but a necessity, ensuring that expectations are met, risks are mitigated, and operations run seamlessly. This is precisely where well-structured manufacturing supply agreement templates become indispensable tools for businesses of all sizes.

These pre-designed legal documents provide a robust starting point for formalizing the critical relationship between a manufacturer and its suppliers, outlining the terms under which goods, components, or raw materials will be provided. For attorneys, procurement professionals, business owners, and legal departments, understanding and utilizing these templates can dramatically streamline negotiations, reduce potential disputes, and solidify operational efficiencies, ultimately safeguarding investments and fostering reliable partnerships.

The Imperative for Formal Agreements in Today’s Business Landscape

The complexity of contemporary global supply chains has never been greater. Geopolitical shifts, technological advancements, and a renewed focus on corporate accountability mean that informal understandings are simply no longer sufficient. Businesses face myriad risks, from fluctuating raw material costs and intellectual property theft to quality control issues and unexpected logistical disruptions. Without a comprehensive, written agreement, parties are left vulnerable to misinterpretations and costly legal battles.

A formal supply contract serves as the bedrock of trust and accountability, clearly delineating responsibilities and expectations for all involved parties. It provides a legally enforceable record of the terms and conditions agreed upon, offering a transparent blueprint for operations. This legal clarity is vital for maintaining stable production, managing inventory effectively, and ensuring consistent product quality, protecting both the buyer’s and seller’s interests in a volatile market.

Advantages of a Well-Crafted Supply Document

Utilizing a manufacturing supply agreement template offers a multitude of benefits that extend far beyond mere legal formality. First and foremost, it establishes a common understanding, preventing ambiguities that often lead to disputes down the line. By detailing payment terms, delivery schedules, quality specifications, and dispute resolution mechanisms upfront, the template minimizes the need for protracted negotiations and clarifies each party’s obligations.

Furthermore, a comprehensive agreement provides significant legal protection. It defines liability limits, intellectual property rights, and confidentiality clauses, shielding businesses from potential financial losses, reputational damage, and the unauthorized use of proprietary information. The structure provided by a template also promotes efficiency, allowing businesses to adapt and finalize agreements quicker, accelerating time-to-market for new products and securing vital supply lines without unnecessary delays. These templates are essential resources, guiding parties through complex legal requirements and fostering a more secure and predictable business environment.

Tailoring Your Contract Framework for Diverse Needs

One of the most compelling aspects of using a robust manufacturing supply agreement template is its inherent adaptability. While a template provides a standardized structure, its true value lies in its capacity for customization across various industries and specific operational scenarios. A generic contract might not adequately address the unique challenges of, for instance, aerospace manufacturing versus food processing, or the supply of custom-designed components versus off-the-shelf bulk materials.

For highly regulated sectors like pharmaceuticals or medical devices, the template can be modified to include specific compliance clauses, regulatory audit rights, and stringent quality assurance protocols. In technology-driven industries, intellectual property protection, non-disclosure agreements, and provisions for software updates become paramount. Similarly, whether the agreement involves a long-term strategic partnership or a one-time transactional purchase, the core framework can be adjusted to reflect the scope, duration, and financial arrangements, ensuring the document remains relevant and legally sound for the particular context.

Core Components of Any Robust Supply Agreement

Every effective manufacturing supply agreement, regardless of the specific industry, should contain a series of essential clauses that address critical aspects of the relationship. These provisions are the backbone of the contract, designed to anticipate potential issues and provide clear guidelines for resolution.

A comprehensive agreement should ideally include:

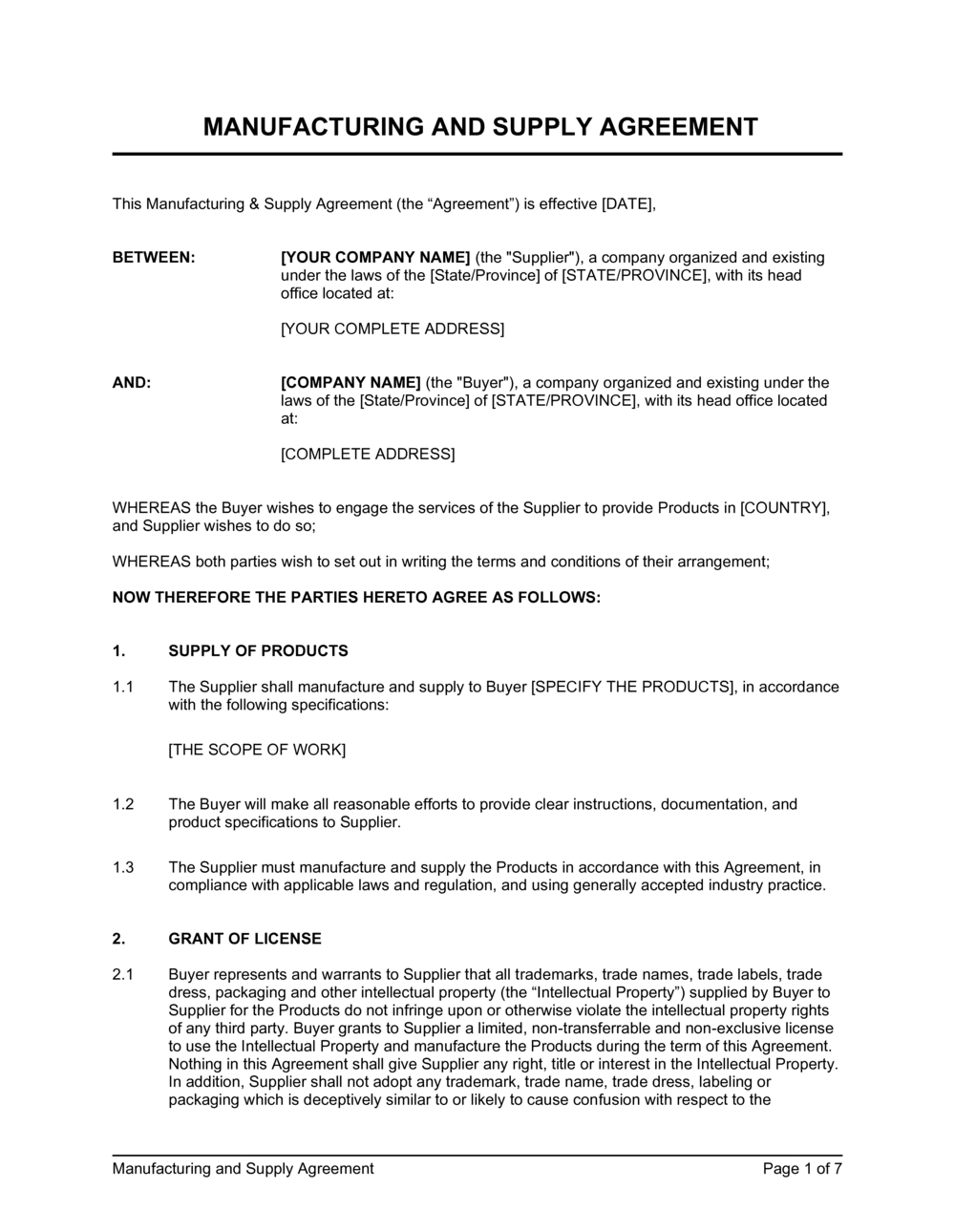

- Identification of Parties: Clearly state the full legal names and addresses of both the buyer (manufacturer) and the supplier.

- Recitals/Background: Briefly explain the purpose of the agreement and the relationship between the parties.

- Scope of Goods/Services: A detailed description of the products, components, or raw materials to be supplied, including specifications, quantities, and quality standards.

- Purchase Orders: Outline the process for placing, accepting, and fulfilling purchase orders, including any minimum or maximum order quantities.

- Pricing and Payment Terms: Specify the agreed-upon prices, pricing mechanisms (e.g., fixed, cost-plus, indexed), payment schedules, currency, and methods of payment.

- Delivery and Logistics: Define delivery dates, locations, shipping methods, responsibilities for freight and insurance (Incoterms are often used here), and acceptance procedures for delivered goods.

- Quality Control and Inspection: Detail procedures for inspection, testing, and acceptance of goods, as well as remedies for non-conforming products (e.g., repair, replacement, refund).

- Warranties: State the supplier’s warranties regarding the quality, suitability, and freedom from defects of the supplied goods.

- Intellectual Property Rights: Address the ownership and use of any intellectual property involved in the design, manufacture, or supply of the goods.

- Confidentiality: Include provisions to protect proprietary information exchanged between the parties during the term of the agreement.

- Term and Termination: Specify the duration of the agreement and the conditions under which either party may terminate it (e.g., breach, insolvency, mutual agreement).

- Indemnification: Clauses detailing which party will be responsible for losses, damages, or legal expenses arising from certain events, such as product defects or intellectual property infringement.

- Force Majeure: Provisions excusing non-performance due to unforeseeable circumstances beyond the parties’ control (e.g., natural disasters, war, pandemics).

- Dispute Resolution: Outline the process for resolving disputes, which may include negotiation, mediation, arbitration, or litigation in a specified jurisdiction.

- Governing Law: Indicate the state or national laws that will govern the interpretation and enforcement of the agreement.

- Entire Agreement: A clause stating that the written contract constitutes the sole and entire agreement between the parties, superseding all prior discussions.

By meticulously addressing each of these elements, a manufacturing supply agreement templates ensures that all critical aspects of the business relationship are clearly documented and legally enforceable.

Enhancing Usability and Readability

Beyond the legal substance, the practical presentation of a supply agreement significantly impacts its usability and overall effectiveness. A document, no matter how legally robust, loses its value if it’s difficult to read, understand, or navigate. For both print and digital use, careful attention to formatting is crucial.

Employ clear, professional fonts (e.g., Arial, Times New Roman, Calibri) at a readable size (10-12 points) and ensure adequate line spacing to prevent text from appearing dense. Use bolding for headings and key terms to draw attention to important sections, but avoid overuse, which can create visual clutter. Paragraphs should be concise, ideally 2-4 sentences, breaking down complex ideas into manageable chunks. Numbered or bulleted lists, as seen in the clauses section above, are excellent for presenting specifications, obligations, or enumerated points with clarity. For digital distribution, ensure the document is easily searchable and can be converted into various formats (e.g., PDF) without losing its structure. A logically organized document, with a table of contents for longer agreements, allows stakeholders to quickly locate specific information, saving time and reducing potential frustration.

In an increasingly interconnected and often unpredictable global economy, the strategic deployment of reliable manufacturing supply agreement templates is a hallmark of sophisticated business operations. These foundational documents transcend simple paperwork; they are powerful instruments that codify trust, manage expectations, and fortify supply chains against a myriad of potential disruptions. Their judicious use allows businesses to focus on innovation and growth, confident in the legal framework underpinning their critical supply relationships.

By providing a clear, customizable, and legally sound blueprint, a well-implemented manufacturing supply agreement templates offers invaluable peace of mind. It streamlines the contractual process, minimizes legal exposure, and fosters more transparent and productive partnerships. Ultimately, leveraging these templates is not just about compliance; it’s about building a resilient, efficient, and legally protected operational future for your manufacturing enterprise.